400-698-6306

400-698-6306

400-698-6306

400-698-6306

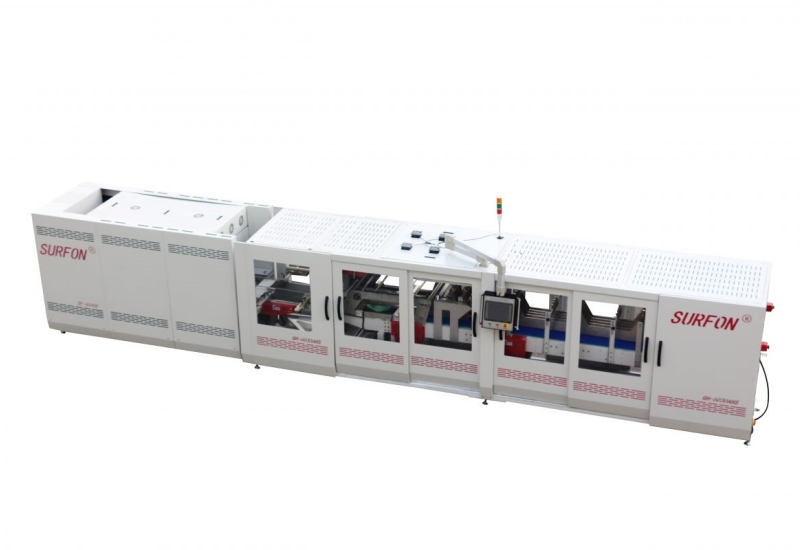

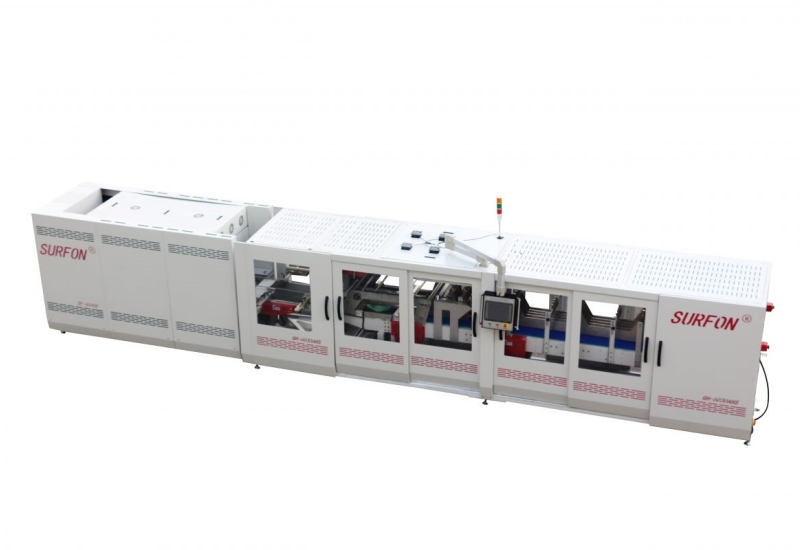

GH-6030AHS+SF-6040E

is a fully automatic, unmanned sealing and shrinking packaging machine

independently developed by our company. It integrates with production

lines to automatically perform feeding, conveying, film wrapping,

sealing, and shrinking in one continuous process. As a result, it is

widely used in high-volume production line packaging operations,

delivering high efficiency.

GH-6030AHS

is a linear packaging machine custom-designed for bottle-shaped

products similar to "Bee & Flower" hair conditioner. It features

automatic lane dividing (1 into 4), alignment, film wrapping, and

sealing, significantly saving labor and space.

Key Features:

Safety & Visibility:

Enclosed design enhances safety, while viewing windows provide clear

visibility of the packaging process. External touchscreen display and

operation improve user convenience.

Drive System:

Uses original imported motors for stable conveying, pushing, and

sealing. Core components are driven by servo motors for higher

efficiency.

Sealing Blade: Specially designed blade ensures strong seals without cracking or sticking.

Shrinking System (SF-6040E): Dual air-circulation motors ensure even heat distribution in the chamber for aesthetically pleasing shrinkage results.

Conveyance:

Solid steel rods sheathed in imported silicone tubes provide durable

chain-rod conveying. Different conveyor chain materials can be used for

various products.

Cooling: A cooling fan at the discharge outlet rapidly cools and sets products after shrinking.

Control System:

Equipped with Siemens PLC and intelligent touchscreen for integrated

mechanical, electrical, and pneumatic control. Includes safety

protection, alarms, and frequency converter for stepless speed

adjustment.

Reliability: Original imported electrical components reduce operational failures.

Applications:

Suitable for shrink packaging of round products without trays, such as

beer, mineral water, cans, glass bottles, and plastic bottles.