400-698-6306

400-698-6306

400-698-6306

400-698-6306

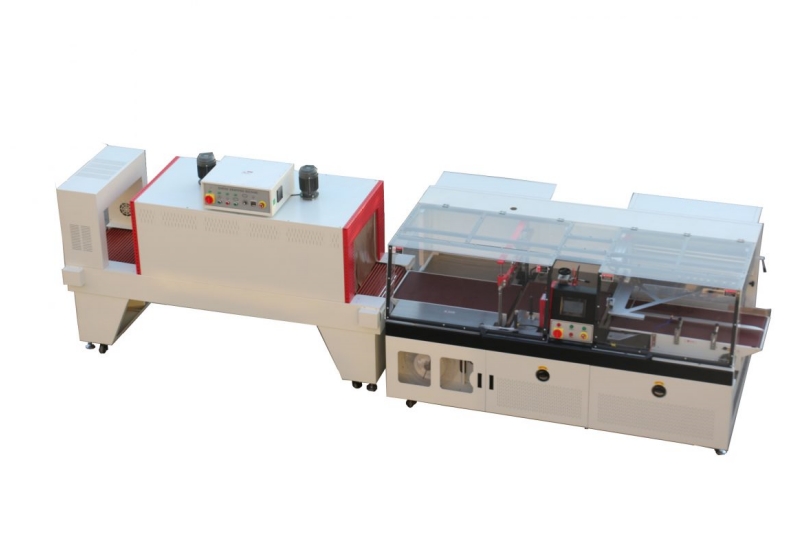

GH-5030LH Fully Automatic Unmanned Edge Sealing Machine

1. Product Overview

The

GH-5030LH is a specialized fully automatic unmanned edge sealing

machine independently developed by our company. It is widely used in

high-volume integrated production lines that combine automatic feeding,

conveying, sealing, and shrinking processes. The machine delivers high

working efficiency and accommodates products of varying heights and

widths.

2. Sealing System

Horizontal blade with vertical drive system

Internationally advanced constant-temperature side blade

Straight and robust sealing lines ensure precise center positioning

Achieves flawless sealing results

3. Structural Advantages

Unique rear-positioned cross-sealing blade (differs from conventional side sealers)

Prevents film displacement during tall product packaging

4. Operational Features

Manual wheel adjustment for quick size changes

Enhanced reliability and simplicity

Suitable for large and tall products

5. Control System

Advanced Siemens PLC programmable controller

Integrated safety protection and alarm systems

Continuous sealing operation without blade replacement

Simplified maintenance requirements

6. Precision Control

Film length control through photoelectric sensors + timer relays

Accurate shrinkage effect management

7. Detection System

Horizontal and vertical photoelectric sensors (two sets)

Easy switching between thin or small packaging items

8. Additional Functions

Automatic edge trimming: Independent motor control prevents loosening/tightening/tearing

Easy waste removal

Automatic air blowing function

Optional powered infeed conveyor and non-powered outfeed table

SF-8040E Shrinking Tunnel Specifications

9. Heating System

Stainless steel heating elements with auto-cooling function

Extends machine lifespan by over 3 times

Adjustable shrinking temperature and conveyor speed

Stable performance with sealed, dust-proof and moisture-resistant packaging

10. Material Compatibility

Suitable for PE shrink film

11. Performance Features

Stable machine performance

High-power circulation motor ensures even heat distribution

Solid 45# steel chain rods with silicone sleeves

Withstands heavy loads while preventing film scorching

12. System Integration

Compatible with automatic and semi-automatic sealing machines

Enables simplified operational workflow

| Model | GH-5030LH | SF-8040E |

| Power | 3kw | 28kw |

| Voltage | AC 380V 3PH 50/60Hz | AC 380V 3PH 50/60Hz |

Maximum Packaging Dimensions L×W×H | L(不限); 430 | 1500x600x300mm |

| Heat Tunnel Dimensions | / | 1800×800×400mm |

| Sealing/Shrinking Temperature | 0-300℃ | 0-300℃ |

| Cutting Blade Length | 900mm | / |

| Workbench Height | 820±50mm | 820±50mm |

| Packaging Speed | 15m/min. | 0-15m/min |

| External Air Supply | 6-8kg/cm2 | / |

| Shrink Film | PE | PE |

Machine Dimensions L×W×H | 3435×1805×1472mm | 2800×1200×1895mm |

Wooden Case Dimensions L×W×H | 3485×1855×1660mm | 2850×1250×2045mm |

| Gross/Net Weight | 1700/1400kgs | 900/780kgs |