400-698-6306

400-698-6306

400-698-6306

400-698-6306

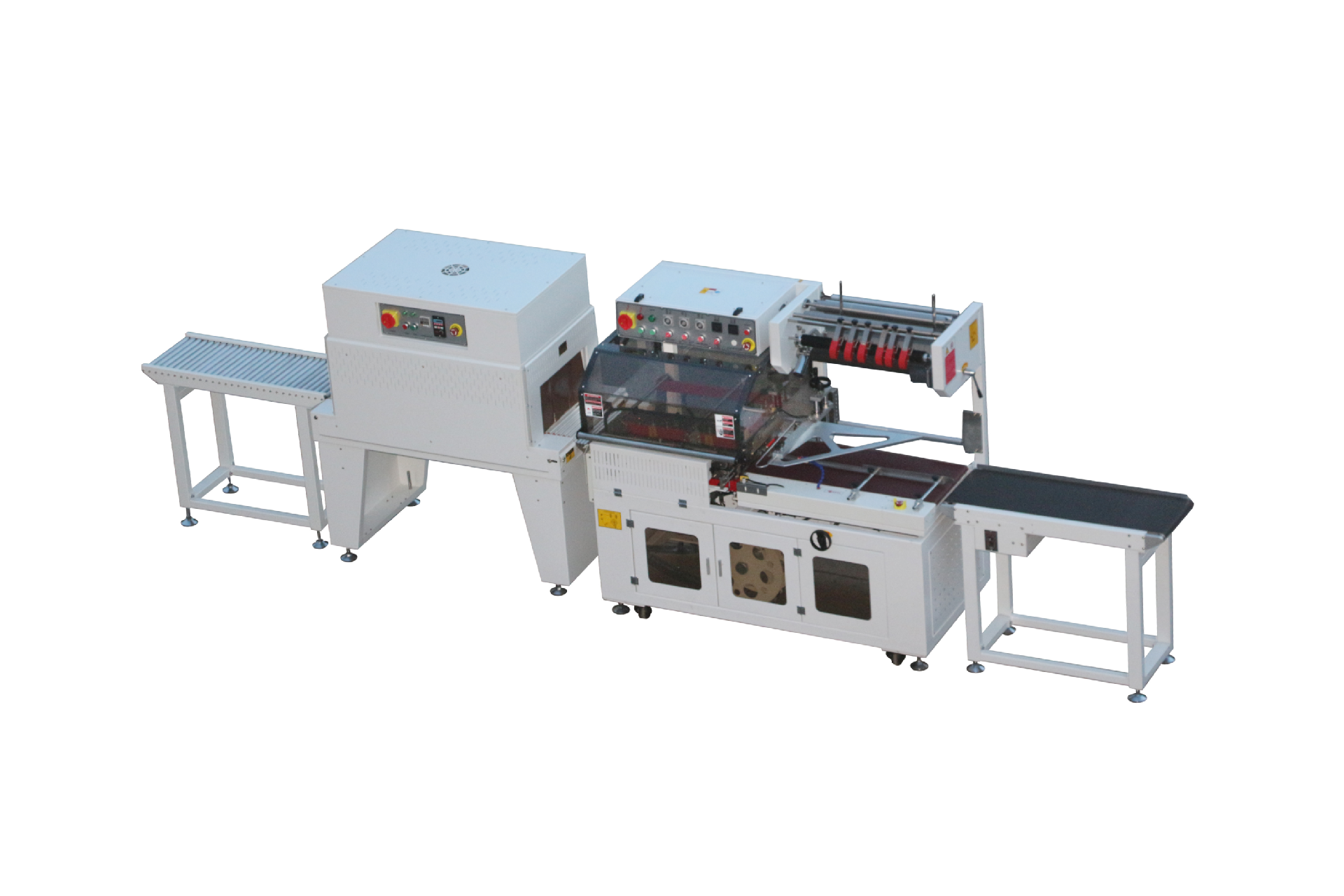

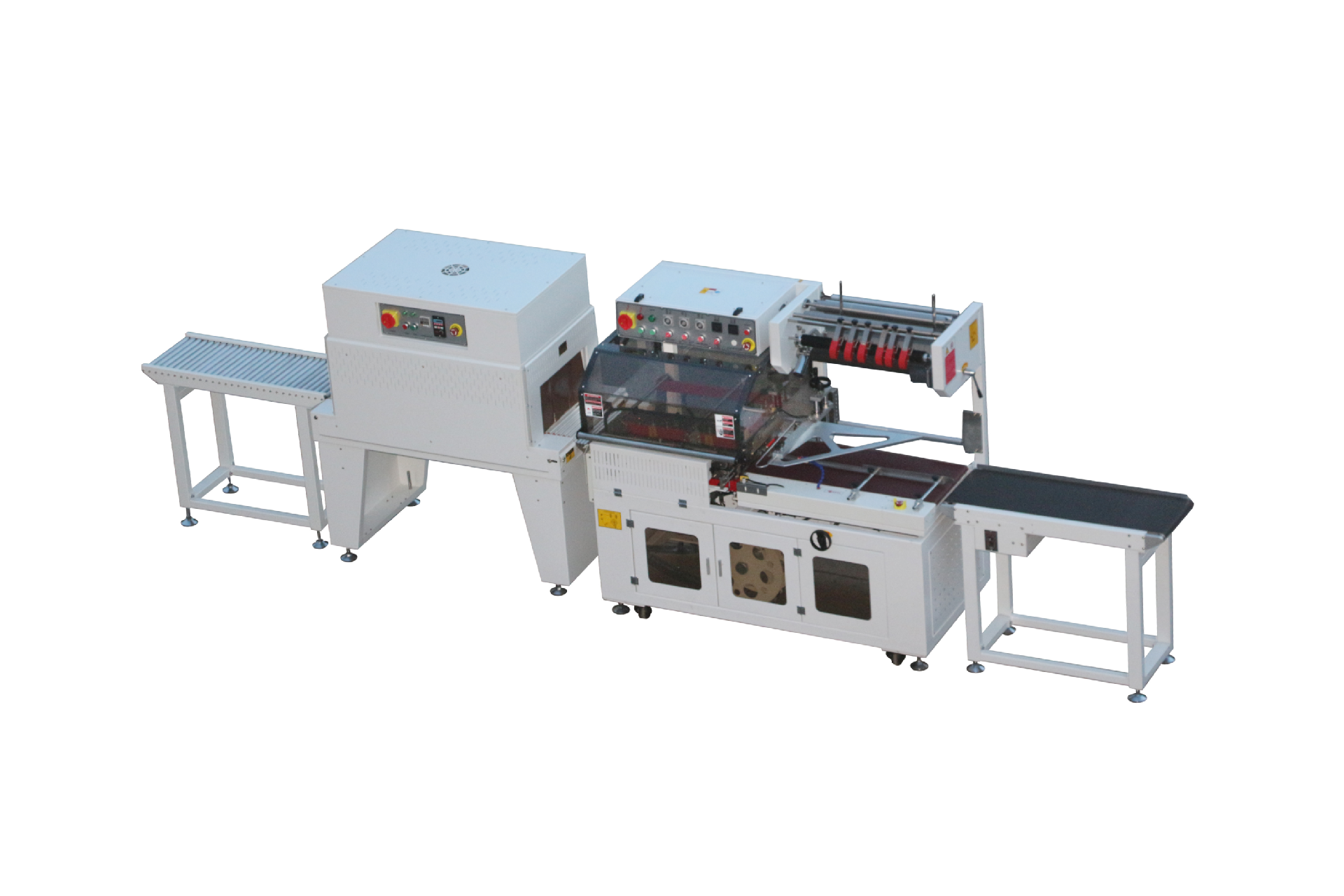

SF-400LA/SF-LAC Series Technical Specifications

Core Product Profile

SF-400LA

is a fully automatic unmanned L-type sealing and cutting machine, ideal

for high-volume production line packaging with exceptional efficiency

Integrated automatic film feeding/perforation mechanism and manually adjustable film guiding system

Versatile feed conveyor platform accommodates products of varying dimensions

SF-400LAC model features specialized close-contact functionality for small-item packaging

Advanced Sealing System

Sealing blade with DuPont Teflon coating and high-temperature resistant aluminum alloy

Prevents cracking, charring, and smoking while ensuring zero contamination

Precision Detection System

Imported photoelectric sensors (horizontal and vertical detection sets)

Flexible switching capability between detection modes

Ensures reliable sealing performance for thin and small packaging items

Automated Operation Features

Automatic feeding with length adjustment via photoelectric sensor and timer integration

Induction motor-driven automatic waste film winding system

Manual wheel adjustment for quick size changes without mold replacement

Temperature Control & Safety

Original "AUTONICS" PID digital temperature controller

Highly responsive and precise sealing blade temperature control

Built-in blade protection prevents accidental product damage

Polycarbonate protective shield with automatic alarm system

Specialized Functions

Specially designed film synchronization mechanism prevents misalignment

Optional tear-notch functionality available

Full production line integration capability for unmanned operation

Supports combination packaging for promotional effects

Industry Applications

New energy, food, cosmetics, printing, pharmaceuticals, building materials

Financial sector, e-commerce logistics, hardware industries

Suitable for ultra-large volume shrink packaging applications

SF-4525 Shrinking Tunnel Features

Stainless steel heating elements with automatic heat dissipation

Extends machine service life by over 3 times

Adjustable temperature and conveyor speed with stable performance

Creates sealed, dust-proof and moisture-resistant packaging

Material Compatibility & Performance

Compatible with POF, PP, OPS and cross-linked films

High-power circulation motor ensures even heat distribution

Solid 45# steel roller shafts with silicone sleeves

Withstands heavy loads while preventing film scorching

System Integration

Compatible with fully automatic and semi-automatic sealing machines

Enables simplified operational workflow

| Model | SF-400LA | SF-4525 |

| Power | 2.2kw | 9kw |

| Power Supply | AC 220V 1PH 50Hz | AC 380V 3PH 50Hz |

| Max. Packing Size L×W×H | L+H≤530mm W+H≤430mm H≤135mm | 1000×300×200mm |

| Max. Sealing Size L×W×H | L550×W450mm | / |

| Packing Speed | 15m/min. | 0~20m/min. |

| External Air Source | 6-8kg/cm2 | / |

| Shrink Film | POF | POF |

| Machine Size L×W×H | 1810×880×1600mm | 1300×800×1520mm |

| Packaging Size L×W×H | 1860×930×1750mm | 1350×850×1670mm |

| G./N. Weight | 483/453kgs | 270/240kgs |