400-698-6306

400-698-6306

400-698-6306

400-698-6306

Morning News Special Issue Report

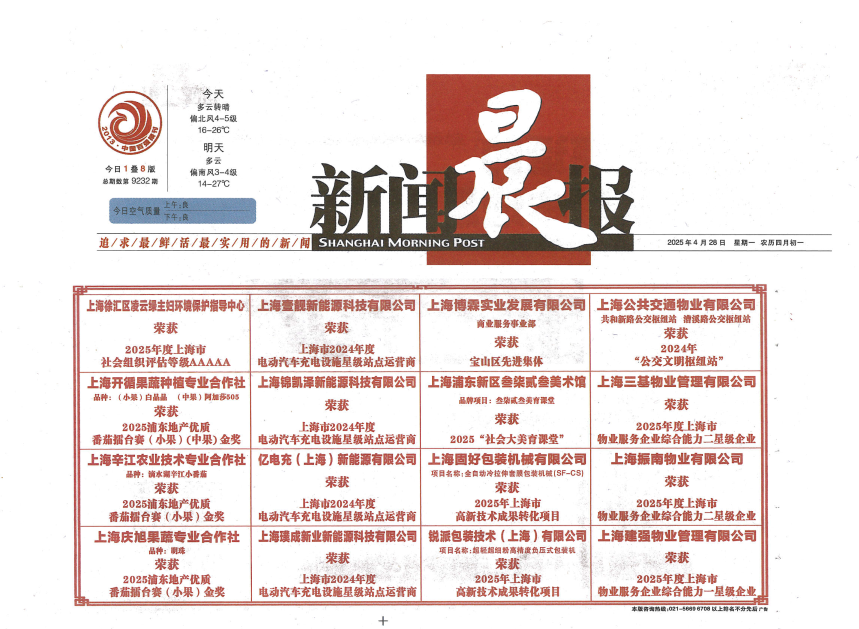

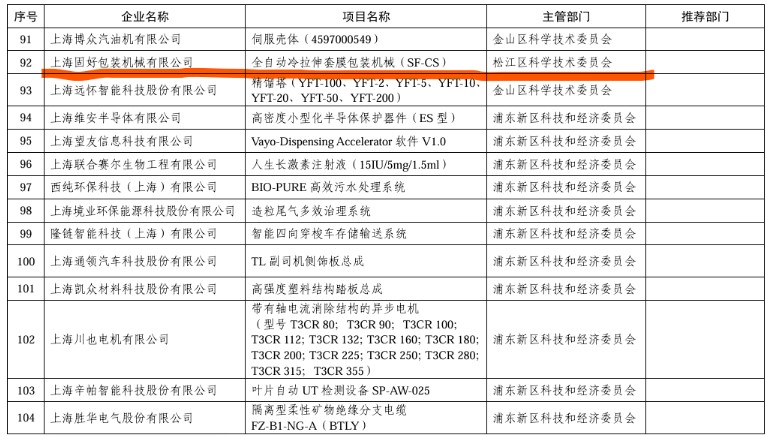

In April 2025, the Shanghai Municipal Science and Technology Commission announced the latest batch of high-tech achievement transformation projects, and the automatic cold stretch hood packaging machine (SF-CS) independently developed by KUKO was successfully selected as a municipal key project with its energy-saving, efficient, safe and intelligent technological breakthroughs. As the core product of KUKO in the field of green packaging, this equipment marks the realization of key technology independence in the field of high-end equipment manufacturing and provides a Chinese solution for the global logistics packaging industry.

Technological Breakthrough: Energy Consumption Reduced by 70%, Theft Rate close to Zero

SF-CS Cold Stretch Hooding Machine replaces the traditional heat shrink process with cold stretch film technology and achieves three major innovations:

Zero-energy heating: The physical stretching process is adopted, which does not require a high-temperature furnace body, which reduces the energy consumption by 70% compared with the traditional heat shrinking equipment, and can save high electricity costs for a single production line every year;

Anti-damage and anti-theft: After the top of the film is sealed, it forms an integrated waterproof package. The film must be cut to take out the goods, and the logistics theft rate is close to zero;

Modular compatibility: The double-head design can automatically adapt to pallets of different heights from 1.2 meters to 2.3 meters, and supports the efficient packaging of all kinds of bulk goods such as bottled drinks, furniture, electronic components, etc.

Industry Applications: Full Coverage of Photovoltaic, Logistics, and Home Appliance Fields

At present, SF-CS has served leading enterprises such as CATL and Qilu Paper, covering four major scenarios:

PV module PACK line: Customized moisture-proof and dust-proof solution for CATL, which reduces the breakage rate of module transportation;

Cross-border logistics center: The loading density of single-container cargo is increased, and the shipping cost is reduced;

Home appliance warehousing: Improve the utilization rate of storage space and reduce the consumption of wrapping film annually;

Remote O&M platform: Integrates 5G modules to support equipment failure warning and cloud parameter tuning.

Corporate Responsibility: Annual Carbon Reduction of 20,000 tons, Green Supply Chain

Mr. Feng Haiyun, Chairman of KUKO, said: "We have always practiced the concept of 'hardcover goods', and SF-CS reduces carbon emissions by planting 1.1 million trees every year. The company has passed the EU CE certification, and exported the products to more than 160 countries, providing customized packaging solutions for multinational companies such as Johnson & Johnson and L'Oreal. In 2024, KUKO Machinery was awarded the title of New Star Enterprise for Development Contribution in Songjiang District, Shanghai.

Popular articles

Popular articlesKUKO's Automatic Cold Stretch Hood Packaging Machine (SF-CS) was awarded the Shanghai High-Tech Achievement Transformation Project. Green packaging technology leads the industry innovation

2025-04-29KUKO shines at the 2025 Warsaw International Packaging Technology and Packaging Products Exhibition in Poland (WARSAW PACK 2025)

2025-04-09KUKO's "Stepped Self-rotating Heat Shrink Machine" won the Excellence Award of the 4th National Machinery Industry Design Innovation Competition in 2024

2025-02-21KUKO exhibited at GULF PRINT & PACK 2025

2025-01-15KUKO celebrates Christmas, and employees make food together to share the joy

2024-12-25The 4th High-end Forum on Sustainable Development of Packaging and the 2024 Annual Meeting of the Packaging Machinery Professional Committee of Shanghai Packaging Technology Association were successfully held

2024-12-18The commissioning of KUKO's machinery and equipment in Tokyo, Japan was a complete success

2024-12-16KUKO participated in swop 2024

2024-11-19 Popular articles

Popular articles Related news

Related news