400-698-6306

400-698-6306

400-698-6306

400-698-6306

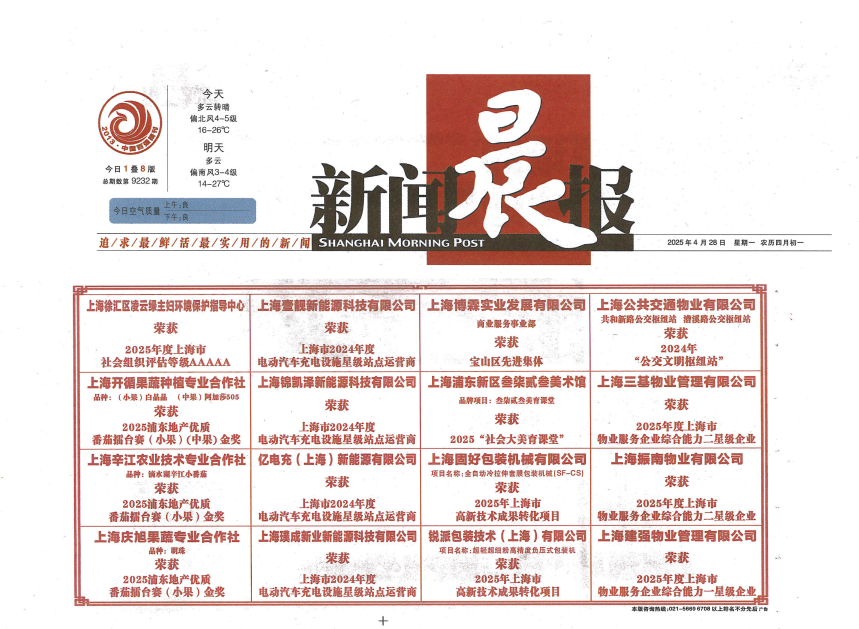

Morning Post Special Report

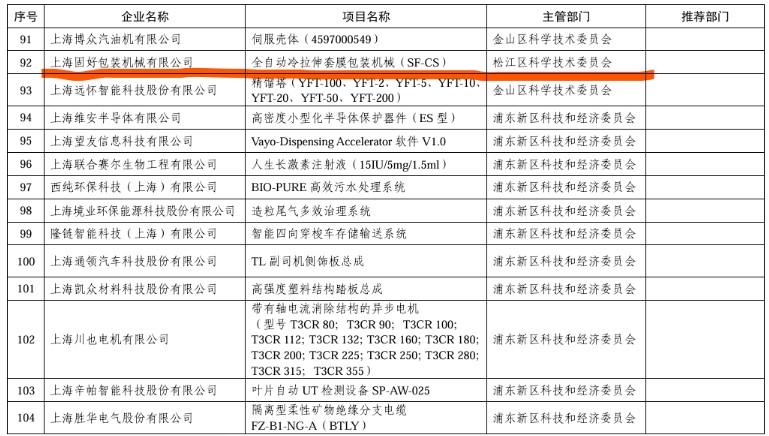

In April 2025, the Shanghai Municipal Science and Technology Commission announced the latest list of high-tech achievement transformation projects. KUKO's independently developed fully automatic cold stretch sleeving packaging machinery (SF-CS) was successfully selected as a municipal-level key project due to its energy-efficient, safe, and intelligent technological breakthroughs. As a core product of KUKO in the green packaging field, this equipment signifies KUKO's achievement in key technology autonomy within the high-end equipment manufacturing sector, offering a Chinese solution to the global logistics and packaging industry.

Technological Breakthrough: 70% Energy Reduction, Theft Rate Nears Zero

The SF-CCS Cold Stretch Sleeving Machine replaces traditional heat-shrink processes with cold stretch film technology, achieving three major innovations:

Zero-Energy Heating: Employs a physical stretching process that eliminates the need for high-temperature ovens, reducing energy consumption by 70% compared to traditional heat-shrink equipment. This can translate into substantial annual electricity savings for a single production line.

Damage & Theft Prevention: The film's top seal creates an integrated, waterproof package; goods can only be accessed by cutting through the film, driving logistics theft rates towards zero.

Modular Compatibility: A dual-head design automatically adapts to pallet heights ranging from 1.2 meters to 2.3 meters, supporting efficient packaging for a full range of loosely stacked goods, including bottled beverages, furniture, and electronic components.

Industry Applications: Full Coverage in Photovoltaics, Logistics, and Home Appliances

Currently, the SF-CS already serves industry leaders such as CATL and Qilu Paper, covering four major scenarios:

Photovoltaic Module PACK Line: A customized moisture and dust prevention solution for CATL has reduced component transportation damage rates.

Cross-Border Logistics Centers: Increased cargo loading density per container has lowered maritime shipping costs.

Home Appliance Warehousing: Improved warehouse space utilization and reduced annual stretch film consumption.

Remote Operation and Maintenance Platform: Integrated 5G modules support equipment failure warnings and cloud-based parameter optimization.

Corporate Responsibility: Annual Carbon Reduction of 20,000 Tons, Green Supply Chain

Mr. Feng Haiyun, Chairman of KUKO, stated, "We consistently uphold the principle of 'excellent packaging for all goods.' The SF-CS reduces carbon emissions annually by an amount equivalent to planting 1.1 million trees." The company's products have obtained EU CE certification and are exported to over 160 countries, providing customized packaging solutions for multinational corporations such as Johnson & Johnson and L'Oréal. In 2024, Guhao Machinery was recognized as a "Development Contribution Rising Star Enterprise" in Shanghai's Songjiang District.

Popular Articles

Popular ArticlesSongjiang Daily Reports on KUKO's "Most Beautiful Production Line"

2023-11-24KUKO Successfully Renews Designation as a Shanghai High-Tech Enterprise

2024-09-11KUKO Makes Its Appearance at SWOP 2025, Presenting Cutting-Edge Packaging Machinery Solutions

2025-12-25KUKO 2025 Christmas Celebration Warm Start, Love and Joy Walk Together

2025-12-25KUKO organizes viewing of the "September 3rd" military parade: technological empowerment of the military inspires the fighting spirit of strengthening the enterprise.

2025-09-04KUKO "Summer Refreshment Campaign": A Bottle of Salt Soda Cares

2025-07-25KUKO and SIEMENS Forge Strategic Partnership to Co-create a New Chapter in Intelligent Manufacturing

2025-07-09KUKO's Fully Automatic Cold Stretch Sleeving Packaging Machinery (SF-CS) Recognized as a Shanghai High-Tech Achievement Transformation Project: Green Packaging Technology

2025-04-29 Related News

Related News